About Us

Camroopine International, established in 2015, is a leading manufacturer of high-quality aluminium extrusion profiles. Based in Surat, Gujarat, we offer precision-engineered solutions, including in-house fabrication (drilling, tapping, laser welding, cutting, CNC machining, bending) and advanced surface treatments like anodizing, PP powder coating, and PVDF coating.

Windows & Doors

Architectural & Curtain Wall Systems

Transportation & Automotive

Electronics & Power Plants

Earth Moving & Telecommunications

Building & Construction

Medical & Healthcare Equipment

Email us

Call us

Why Choosing Us!

At Camroopine International, we are committed to delivering exceptional quality, precision, and reliability. With years of expertise in aluminium extrusion manufacturing, we provide customized solutions, advanced fabrication, and superior surface treatments to meet diverse industry needs. Our dedication to on-time delivery, competitive pricing, and customer satisfaction makes us the preferred choice for businesses worldwide.

Our Services

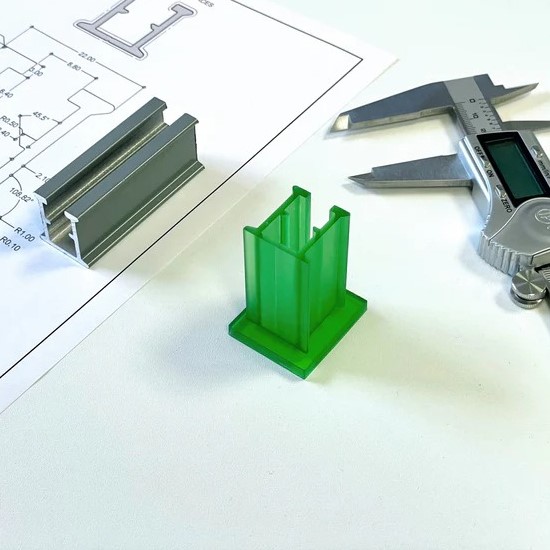

Our clients provide us either 3D design of product or 2D drawings of products. In either case design & prototype is involved.

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening

Cleaning: Removes oils, dirt, and contaminants. Pretreatment: Chemical treatments (e.g., anodizing, chromate conversion) enhance adhesion and corrosion resistance.

Anodizing is an electrochemical process that enhances aluminum's durability, corrosion resistance, and appearance by forming a protective oxide layer.

Laboratory

The laboratory services at Camroopine int guarantee product quality through extensive analysis and testing before and after any process has been approved for production.

Our Capabilities

Drilling involves creating round

holes in aluminum profiles for

various purposes, such as

assembly, fastening, or design.

Tapping refers to cutting

internal threads into pre-drilled

holes to allow screws or bolts to

be inserted and tightened.

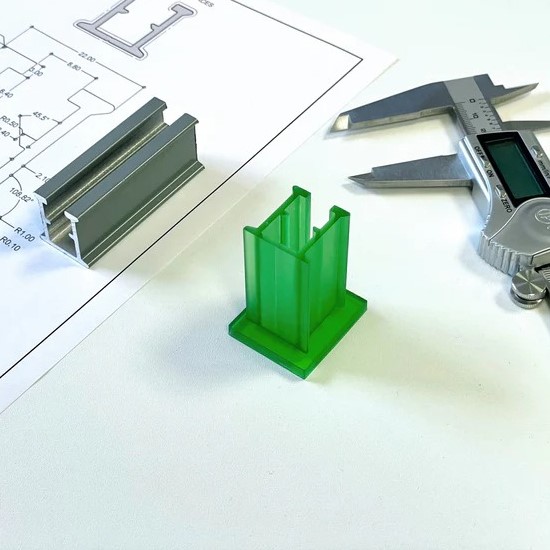

Laser welding is a high-precision

process that uses a focused laser beam

to join aluminum pieces together. The

high heat generated by the laser melts

the aluminum at the weld joint, fusing

the parts.

This process provides clean, strong

welds with minimal heat distortion,

making it suitable for thin or

delicate aluminum profiles.

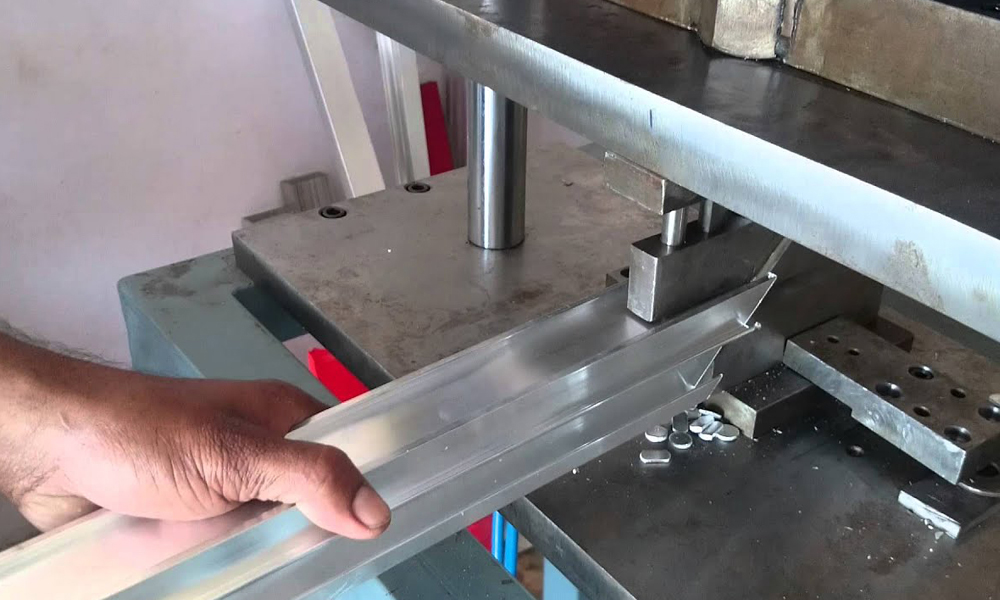

Aluminum profiles can be cut using various

methods, including sawing, laser cutting,

water jet cutting, or plasma cutting.

Sawing is often used for straight cuts.

Laser cutting offers high precision for

intricate shapes and complex cuts.

Water jet cutting uses high-pressure

water to cut, leaving smooth edges with

no thermal distortion.

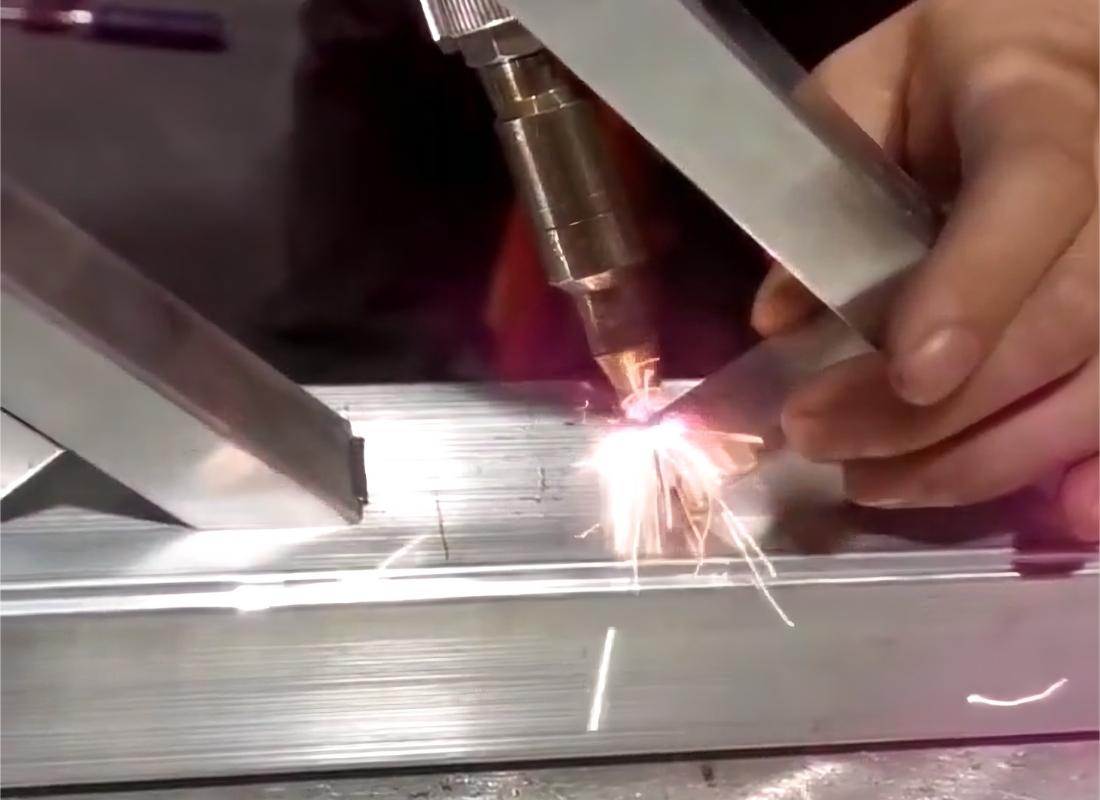

Punching is used to create holes or

other shapes in aluminum profiles by

using a die and punch tool.

The process involves applying force to

push the punch through the aluminum,

creating holes or indentations. This

can be done for assembly, ventilation,

or aesthetic purposes.

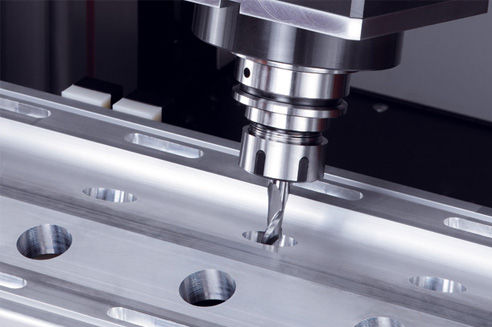

CNC machining involves the use of computer-

controlled machines to perform various

operations like drilling, milling, turning,

and threading on aluminum profiles.

CNC machining provides high precision and

allows for complex and custom shapes, which

makes it ideal for intricate designs.

Bending is the process of deforming aluminum profiles to create angles or curves. This is typically done using a press brake or roll bender. Aluminum profiles can be bent to a variety of angles, depending on the requirements of the product. Bending is commonly used for frames, brackets, or parts requiring specific shapes to fit into assemblies.

© Camroopine International, All Rights Reserved.

Designed By Aimers Infotech